PHOENIX

TU/ecomotive’s

We're tackling the waste crisis head-on, Phoenix sets an example for efficient closed-loop recycling as 75% of its materials can be reused to build future cars.

Tim van Grinsven - Team Manager

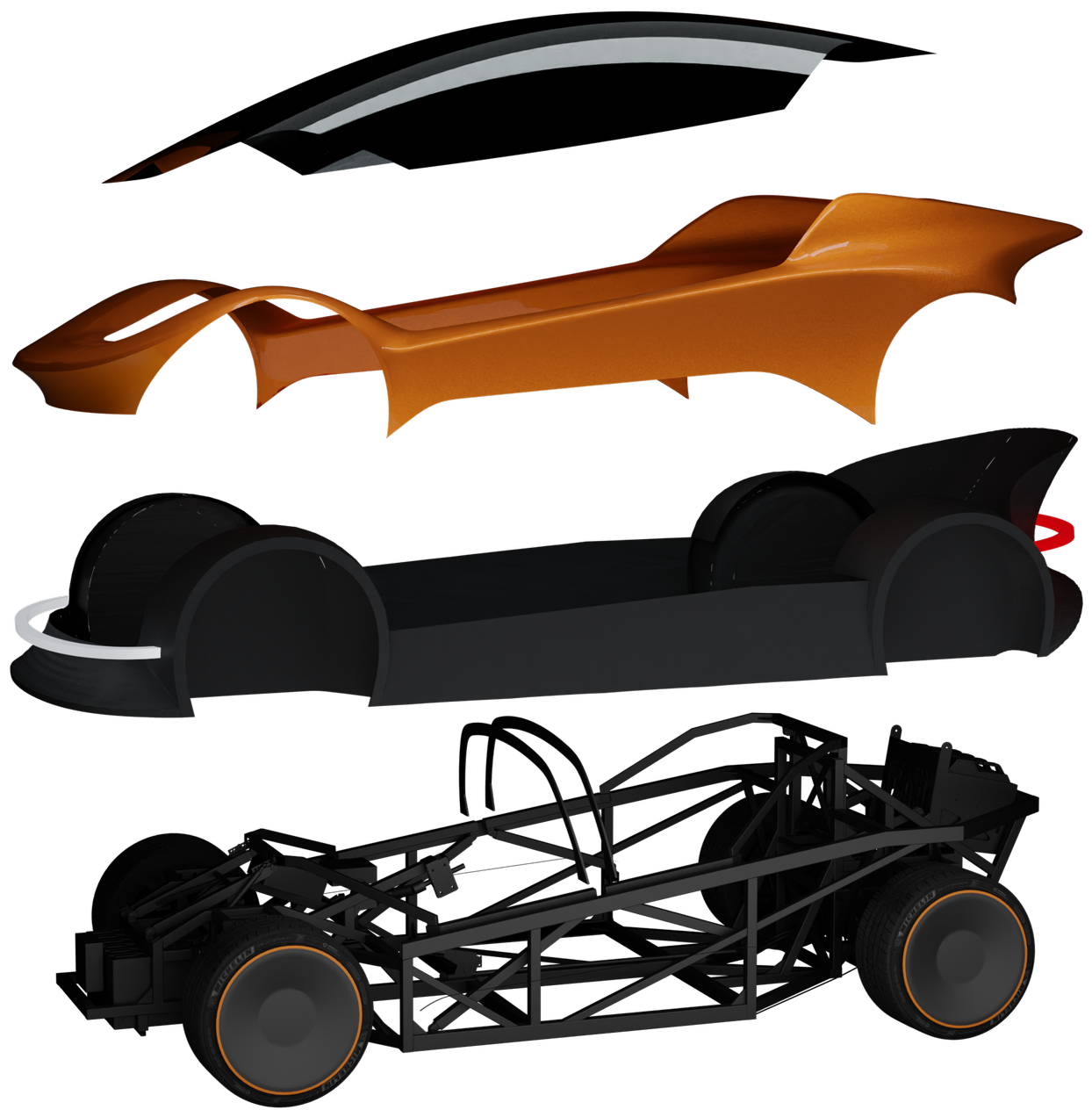

What makes Phoenix unique is that its materials can be closed-loop recycled up to 75%, where materials can be recovered and reused in their original state for new products of the same kind. Currently, this percentage is at 21% in the automotive industry, but the European Commission is on a path in significantly increasing this number.

The secret lies primarily in the mono-material structures, utilizing a minimal variety of materials, and smart attachment methods where materials are not permanently bonded together. As a result, the quality of the materials does not degrade quickly after reuse, and recycling efficiency is improved.

220KM Range

-

110KM/H Top Speed

-

75% Closed Loop Recycling

-

220KM Range - 110KM/H Top Speed - 75% Closed Loop Recycling -

Expertise Areas

As the TU/ecomotive design team, we interacted with stakeholders throughout the process, including our own engineers from within the team, but also industry professionals from our partner companies. These companies are varied in nature, from materials suppliers to manufacturing partners. Effective communication and collaboration within this ecosystem was essential for the design team to manage the process of effectively translating our design to reality.

Business & Entrepreneurship

One of the primary takeaways for myself as a designer from the experience of being a part of the Ecomotive design team was the importance of visual communication of design concepts. Effectively translating the design concepts to reality through materiality and aesthetic quality was something we strived for throughout the design process.

Creativity & Aesthetics

TU/ecomotive is a multidisciplinary student team of 30+ engineering students that work in sub-teams. Communicating design concepts and narratives to designers and, inversely, understanding their engineering constraints required a constant dialogue between the design group and the various sub-teams. Negotiating design choices with engineering feasibility was an incredibly enjoyable challenge from my perspective.