THE FUTURE OF SHOES.FLEX

What did we do?

The team identified a common interest in expandable and flexible products early on in the design process. The project aims to explore and create samples using this area of interest as a starting point for a material exploration driven process.

-

02/2023 [20 weeks]

-

Material-driven design, 3D printing, weaving, and more…

-

S. Janssen, N. van Kuijk, M. van Strien

-

Business & Entrepreneurship, Creativity & Aesthetics, Users & Society

Objectives

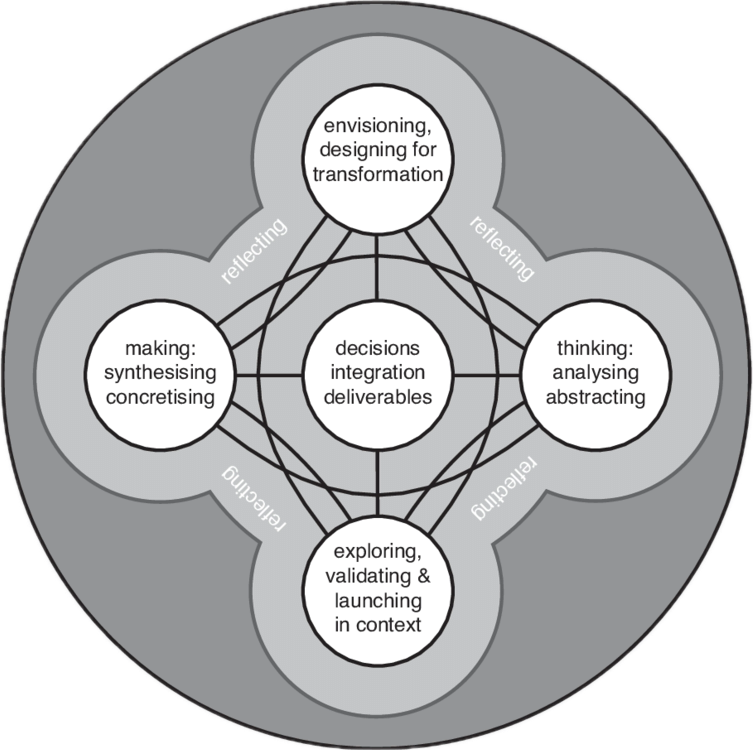

Understand the reflective-transformative design process

Focus on the expertise areas of Technology & Realization, Creativity & Aesthetics and Users & Society.

MATERIAL EXPLORATION

-

MATERIAL EXPLORATION -

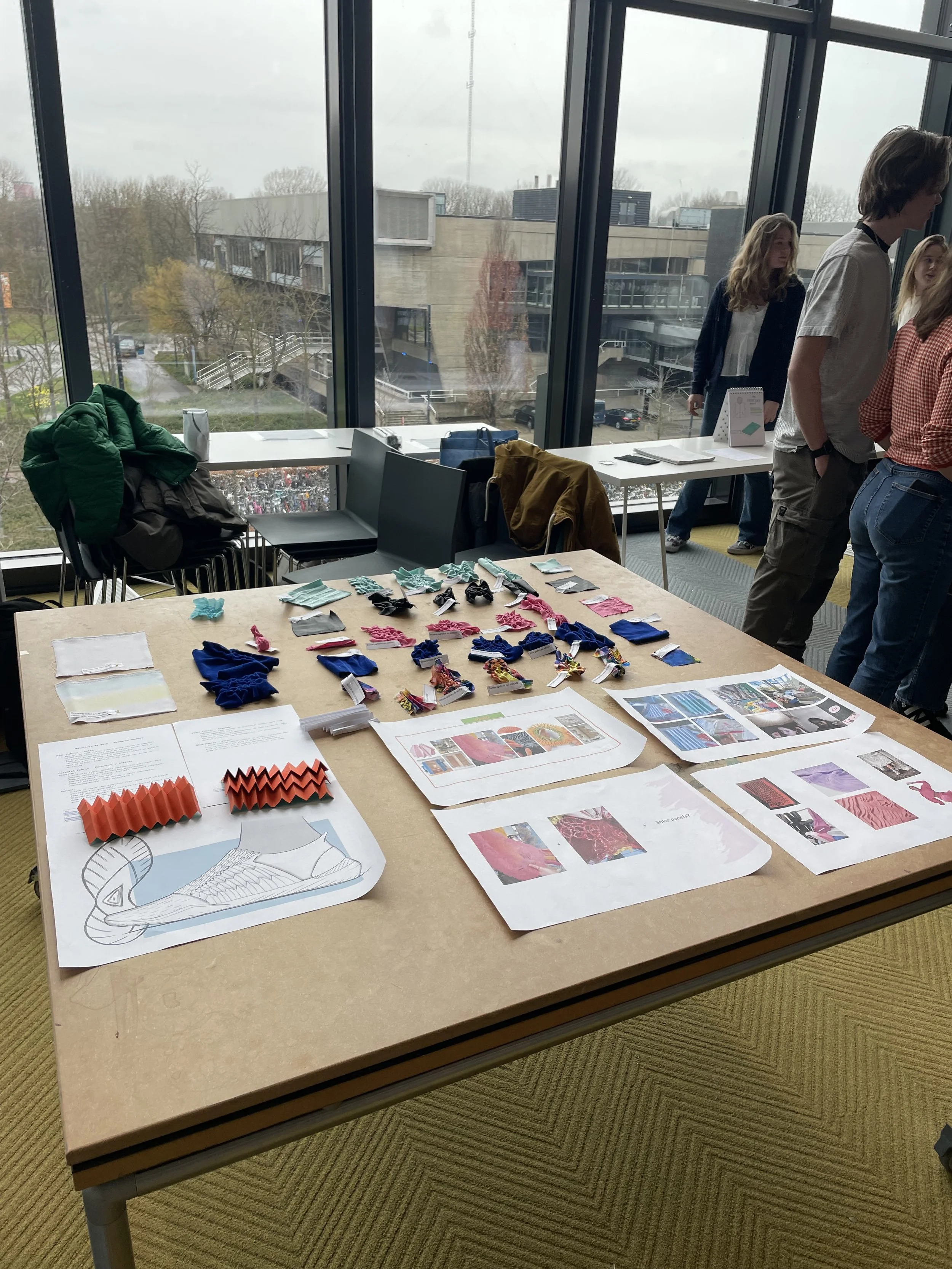

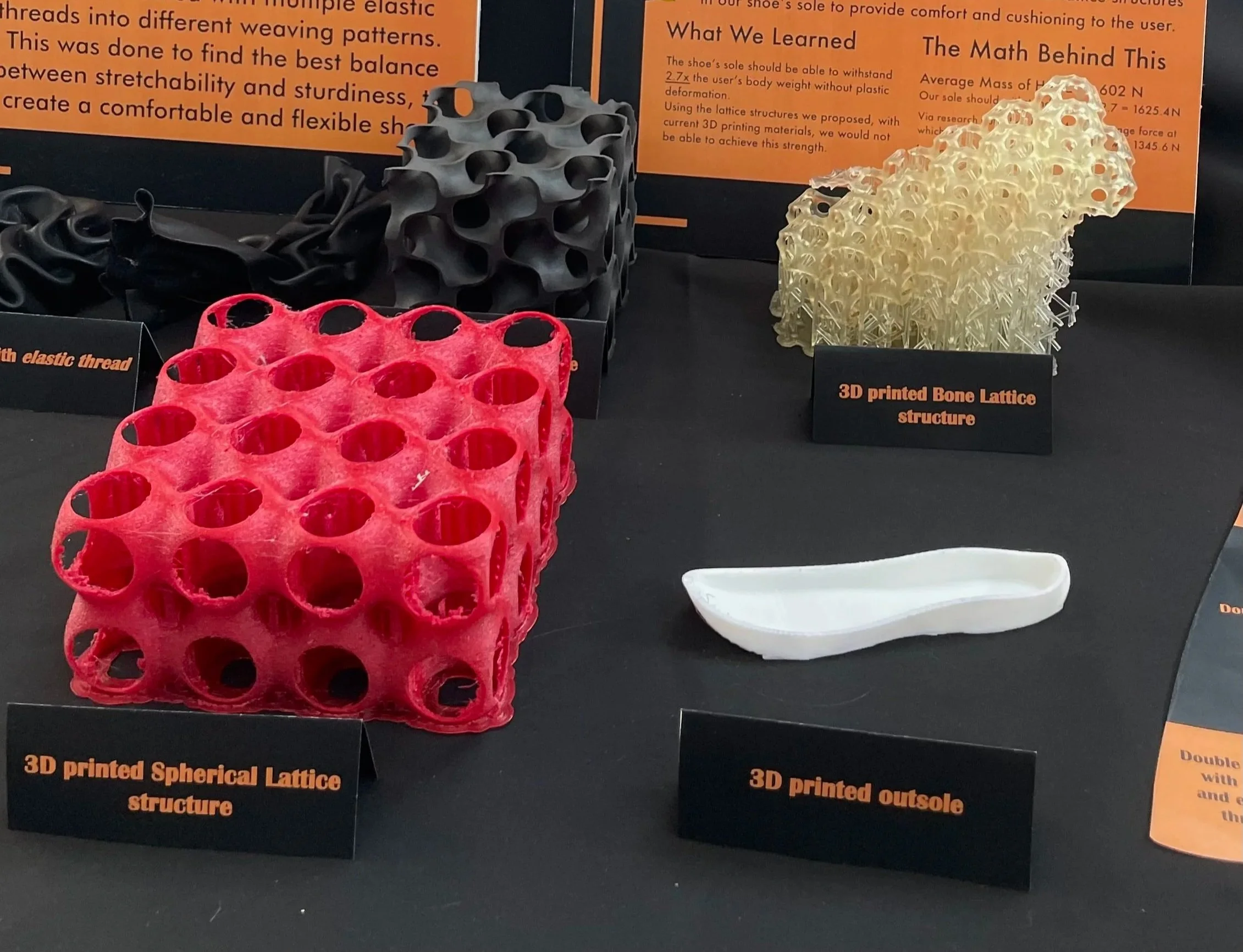

The team deployed a hands-on approach that focused on generating ideas and experimenting with various types of fabrics, threads and techniques. Smocking using elastic thread in the ‘bone’ and ‘wave’ patterns resulted in fabrics that were stretchable in one direction, and stiff in the other.

Final Design Outcomes

Expertise Areas

The FLEX team designed a brand identity around the design concept and evaluated business models that could suit our ideas to be framed within society. This was a vital first step into the expertise area of B&E as first-year students that allowed us to present our project at a higher level of refinement.

Business & Entrepreneurship

Creativity & Aesthetics

The use of physical and interactive materiality was a key part of designing the FLEX fabric and in turn the shoes during our numerous experiments and sample making sessions. We also focused on reflecting on our process continually, iterating in logical and reasoned steps.

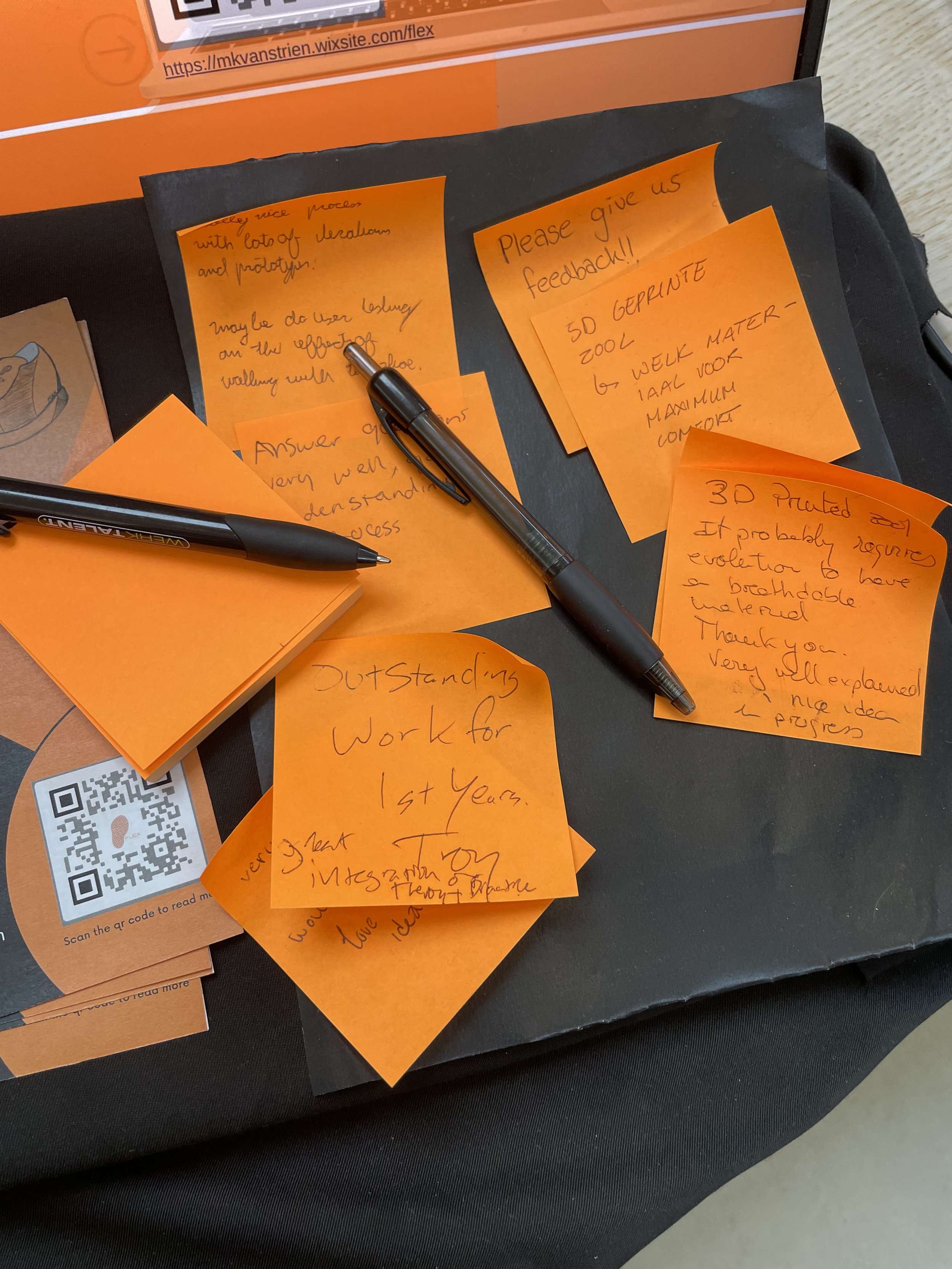

Throughout the design process we engaged in conversation with an industry expert on shoes and 3D printing. With this dialogue we were able to collect valuable insights and validate our design concepts. We also spent time on the positioning of our design in the industry context by examining the work that has been done previously on similar topics.